We offer a comprehensive range of leaf springs that meet the demands of various Vehicles

Explore our product offerings below

Parabolic leaf springs use a single leaf or a few leaves of varying thicknesses to make them parabolic in shape. This design makes them lighter, more flexible, and better at providing a smooth ride while still maintaining the strength necessary for heavy-duty applications. They also reduce noise and wear, which is why they are used on many modern trucks.

A multiple leaf spring is made up of leaves that are all the same width

and thickness. This design can carry a lot of weight by spreading it out across multiple leaves, resulting in a very strong and long-lasting suspension system. That’s why you see multiple leaf springs on heavy-duty trucks. They provide good support and last a long time, even in tough conditions.

Z-type springs are used in air suspension systems on heavy-duty

commercial vehicles such as trucks, trailers, and buses. They help some of the load off the axles and the frame, which makes the ride better for the driver. Z-type springs also help position the axles and control the ride height of the vehicle.

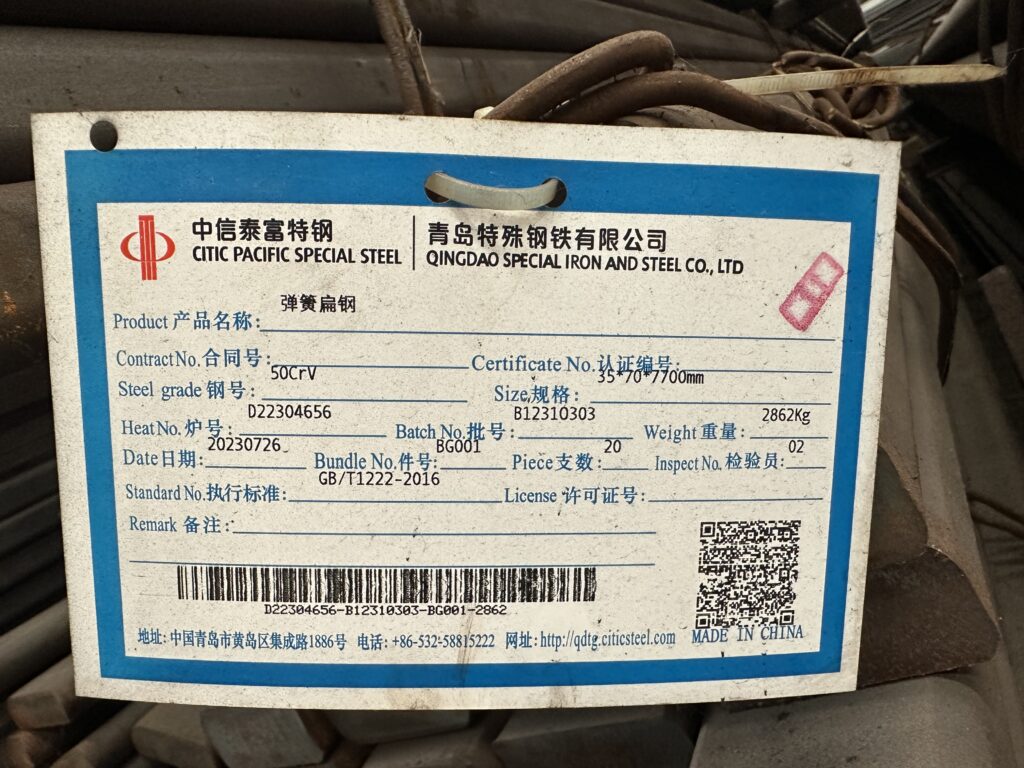

Our raw materials are mainly sourced from state-owned special steel mills. These suppliers are known for their consistent quality and reliable deliveries, and have even participated in the development of China’s steel leaf spring industry standards. Each batch of steel undergoes rigorous quality testing and is accompanied by a quality-traceable information card, ensuring that you receive leaf springs of exceptional intrinsic quality. Our company firmly rejects the use of track steel and raw materials supplied by private steel mills.

the common use materials are SUP9, 50CrV, 51CrV4, 52CrMoV4 for export products.

Welcome to Zikun! We have a fully automated leaf spring production line that uses advanced manufacturing equipment and strict quality control, The capacity is about 350 tons per day! And we sure every leaf spring we produce has great quality and performs well.

We use advanced testing equipment and have a scientific testing process. Our export products 100%

to make sure they work excellent in different situations.

The primary function of a fatigue life testing machine is to simulate the repeated loads that a product experiences during actual use. By applying cyclic stress, it tests the fatigue strength and lifespan of leaf springs. This equipment precisely measures the performance changes of leaf springs under long-term loading, ensuring that the product maintains stable quality and durability across various operating conditions.

The automotive leaf spring salt spray tester is a device used to test the corrosion resistance of automotive leaf springs. By simulating a salt spray environment, this tester is able to evaluate in a short period of time the degree of corrosion that a leaf spring may be subjected to over a long period of time, thus verifying its corrosion resistance and service life. Our leaf springs are capable of passing a 500-hour salt spray test.

Ultrasonic flaw detector is a non-destructive testing equipment for automotive leaf springs and other high-strength key components, it can be used in the production process or finished product inspection for effective quality control, to ensure that there is no defects such as cracks, pores, inclusions and other defects within the product, to avoid fracture due to these defects.

Testing the hardness of leaf springs using an electronic Brinell hardness tester is an important step in assessing their material strength and durability. Usually we will take a certain proportion of the number of leaf springs in the same batch for testing, if there is any inconsistency with the production drawings, we will carry out a full inspection of the batch of products, or rework or eliminate all the products, and will never send unqualified products to the customers!

Material composition testing is particularly important in the manufacture of leaf springs, which require high strength and toughness and are often made from high carbon or alloy steels. The flat steel we purchase is tested for material composition to ensure that the carbon, manganese, silicon, chromium, molybdenum, and other elements in the steel are within the proper ranges for the performance of the leaf springs. If we receive substandard flat steel from a supplier, we will return it and never use it in production.

Can not find your inquriy brand or need custom service? Contact us for more information!

We mainly provide steel plate springs for heavy-duty trucks, including a wide range of sizes and models. All products can be customized to ensure compatibility with various vehicle models.

We adhere to a strict quality control process and all of our leaf springs pass multiple tests to ensure high stability and durability. We use advanced production equipment to ensure the consistency and high quality of our products.

Yes, we provide customized service, we can produce specific specifications of steel plate springs according to customer’s drawings or samples. We have a professional technical team to meet your special needs.

Our production lead time is usually 2 to 4 weeks, depending on the order quantity and customization requirements. We will try our best to ensure fast delivery so that our customers won’t miss the peak selling season.

We have a comprehensive supply chain management system and cooperate with several logistics companies to ensure on-time delivery. In addition, we keep a certain amount of stock to cope with urgent orders.

We accept a variety of payment methods, including Letter of Credit (L/C), Telegraphic Transfer (T/T) and so on. For long-term customers, we can offer credit payment options.

Our website provides a video demonstration of the production process, which you can watch on the “Production Process” page. In addition, you can also contact us to arrange a factory tour.

You can contact us via email (sales@zk-leafspring.com) or the contact form on the website. Please provide us with your requirement information and we will provide you with a detailed quotation as soon as possible.

Can’t find the answer you’re looking for? Reach out to our customer support team.

Have a question or need more information about our leaf springs? We’re here to help. Reach out to us through the following methods:

Have a question or need more information about our leaf springs? We’re here to help. Reach out to us through the following methods: