SUP7: A silicon-manganese spring steel known for its excellent fatigue resistance.

SUP9: Another silicon-manganese steel, offering higher strength than SUP7.

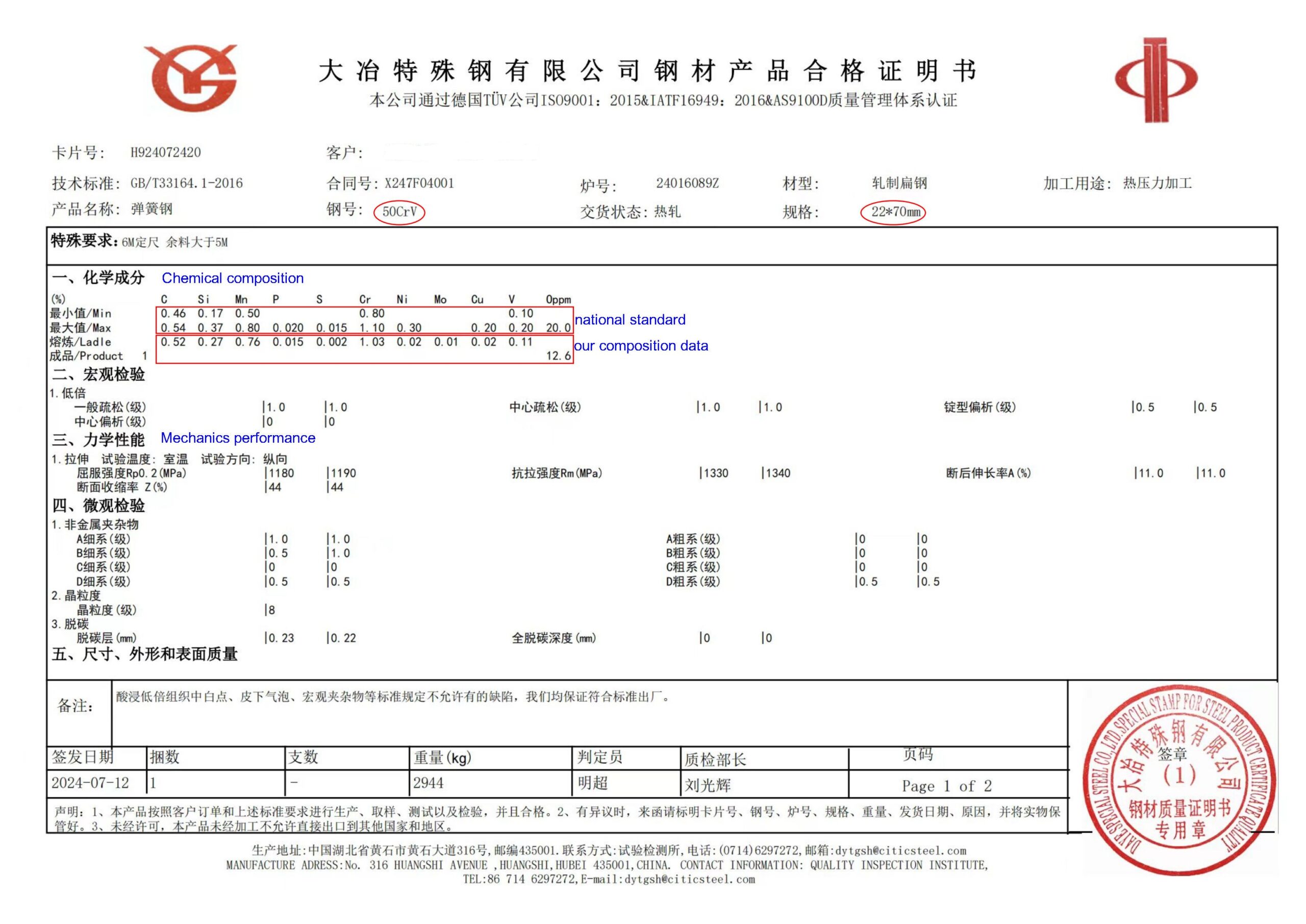

50CrV: A chromium-vanadium steel prized for its toughness and wear resistance.

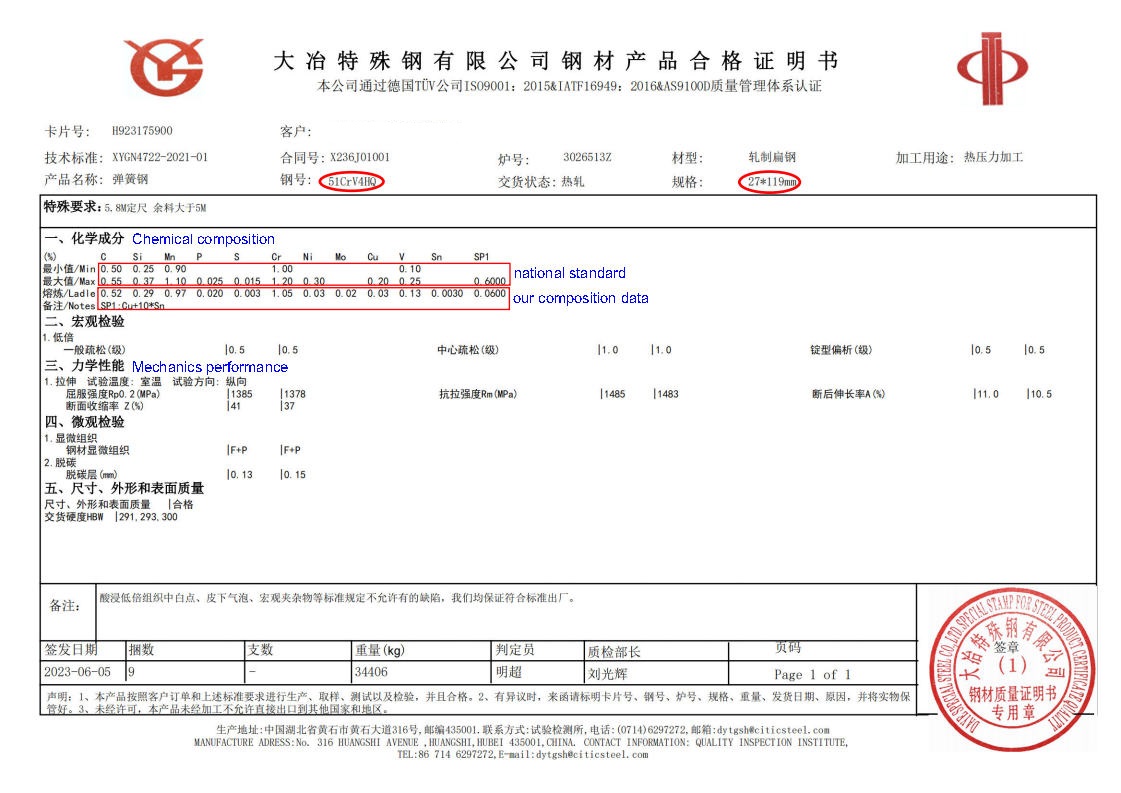

51CrV4: A variant of 50CrV with slightly higher carbon content.

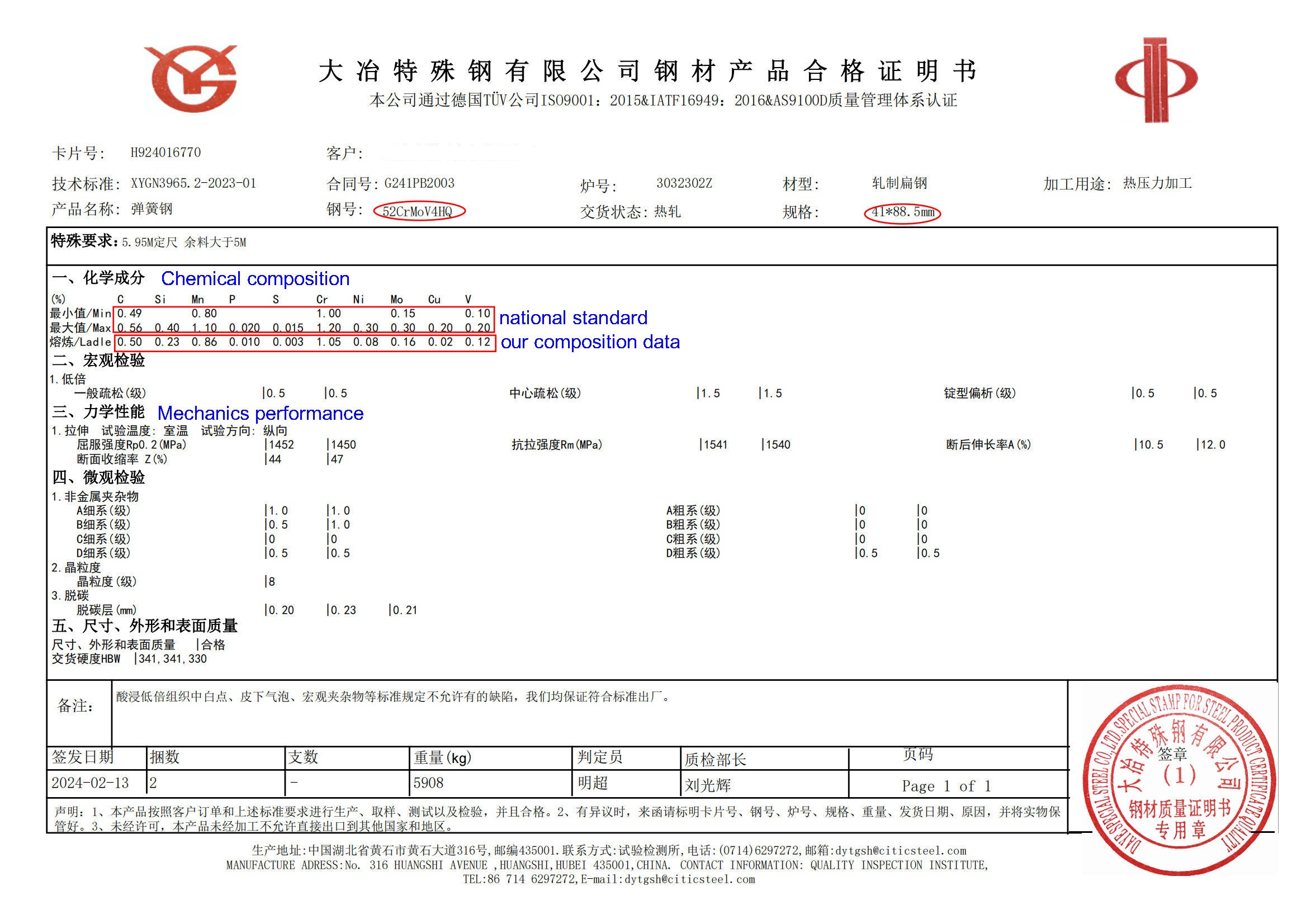

52CrMoV4: A premium grade steel with added molybdenum for enhanced strength and heat resistance.

| Property | SUP7 | SUP9 | 50CrV | 51CrV4 | 52CrMoV4 |

| Applications | Light trucks, medium-duty trucks, buses, construction machinery, and other medium-load vehicles. | Heavy-duty trucks, large construction machinery, mining vehicles, trailers, and other heavy-load vehicles. | Ultra-heavy-duty trucks, mining equipment, large trailers, specialty vehicles, and extreme-duty machinery. | Ideal for leaf springs, coil springs, and torsion bars in automotive and heavy-duty industrial applications. | Primarily used in leaf springs for heavy-duty trucks, industrial machinery, and agricultural vehicles.It is especially suited for extreme load-bearing applications. |

| Thickness and Shape | Typically used in leaf springs with standard thicknesses (6 – 10 mm), especially for conventional spring designs. | Suitable for thicker leaf springs, particularly in the thickness (10 – 15 mm), and complex spring shapes. | Ideal for leaf springs with thicknesses greater than 15 mm, suitable for special shapes and high-load applications. | Commonly available in a range of 15 mm to 35 mm, suitable for Z type leaf springs, depending on specific use cases. | Common thickness varies between 35 mm and 70 mm, suitable for Z type leaf springs, depending on customer requirements. |

| Hardness (HRC) | 44~48 | 46~50 | 45~49 | 46~52 | 47~56 |

In addition, we use raw materials that contain more chemical elements than the industry average, thus ensuring that our leaf springs are more durable. Quality Conformity Certification are available as below:

Conclusion:

Have a question or need more information about our leaf springs? We’re here to help. Reach out to us through the following methods: