When a leaf spring breaks, it can lead to significant consequences for a vehicle’s suspension system, safety, and performance. Leaf springs are vital components that distribute weight, absorb shocks, and ensure a smooth ride. A broken leaf spring disrupts these functions, often resulting in instability, poor handling, and potential safety hazards.

What happens when a leaf spring breaks depends on the cause of failure and its impact on the vehicle’s suspension system.

U-bolts are used to fix the leaf springs to the axle. If these bolts are not tightened properly, they can become loose over time, leading to center bolt failures and the leaf springs will be broken at the center hole position.

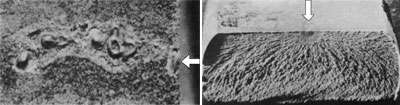

A photo of a typical broken cross-section is shown as below. Please note that if a Leaf spring breaks because U bolt was not tightened, it is usually not covered by the leaf spring manufacturer’s quanlity warranty. it’s better to inspect U-bolts for tightness regularly, especially after 500 miles of use.

Overloading a truck with excessive cargo or towing beyond the vehicle’s capacity puts undue stress on the leaf springs. The leaf springs will be broken at position from clip to eye. Usually users will add some extra leaves on multiple leaf springs to increase the load carrying capacity it is also not covered by quanlity warranty.

Weld splatter, often caused during welding processes on commercial trucks or motorhomes, can damage leaf springs. Even minor contamination can significantly reduce the spring’s lifespan.

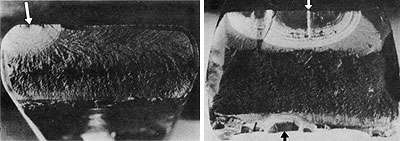

A photo of a typical broken cross-section is shown as below.

Corrosion and fatigue are usually caused by a combination of time in service and environmental factors. The weight of the load you are hauling, the condition of the roads in the area where you live, etc. will all affect the life of your springs. Ensuring that your leaf springs are rinsed of salt and other corrosive substances and are not overloaded will help prevent corrosion and early spring fatigue.

Our leaf springs are usually primed and topcoated to a thickness of 25μ or more and can pass a salt spray test of over 300 hours. With a new electrophoretic paint line coming on line in 2024, the appearance and service life of our products have been greatly enhanced!

A broken leaf spring can cause the axle to misalign or lift off the ground, leading to a rough and unstable ride. This instability can affect handling and make the vehicle unsafe to drive.

The suspension system relies on the leaf spring to distribute weight evenly. A broken spring can place undue stress on other components, causing premature wear or failure.

A failing leaf spring reduces the vehicle’s ability to absorb shocks, increasing the risk of accidents. Poor handling and reduced traction can lead to loss of control.

A broken leaf spring requires immediate replacement, leading to additional maintenance costs. Regular inspections and proper maintenance can prevent such issues.

To avoid leaf spring failure, it is essential to:

In conclusion, a broken leaf spring can have serious consequences, including reduced vehicle stability, increased safety risks, and higher maintenance costs. Regular inspections and proper maintenance are crucial to prevent such failures and ensure the longevity of the suspension system.

Over the years, we have met a leaf spring broken due to inner quality issues. This is because of our strict control of raw materials and production processes, and purchasing our leaf springs ensures that you have a good reputation at upmarket.

Have a question or need more information about our leaf springs? We’re here to help. Reach out to us through the following methods: